Why a 50% Prototype?

It would be completely nonsensical to assume that the development of an eVTOL would be possible without errors and crashes. If all flight tests were carried out with a 1:1 prototype, it would not only be extremely expensive but also very dangerous. The construction and build of a prototype is therefore unavoidable.

Why 50%? The prototype should not be too big, because it will also be very expensive, but it should also not be so small that the flight behavior is extremely different from the real aircraft. I think that 50% represents a pretty good compromise between cost and flight behavior. The most important goal of the pototype is to gain experience with with the flight controller, the Ardupilot software and all the required technology. The prototype also serves to test the planned safety measures.

Frame

Since the real FlyRider will become 2 meters wide and 2 meters long, the prototype is 1 by 1 meter. The frame is built from 15 mm aluminum square tubes.Propulsion

Motors for the prototype are EMAX MT-2216, according to the supplier they shall provide 0,95 kg of thrust with a 10 x 4.5 prop at 14,8 V (4S)

and 14.6 A. The real FlyRider aircraft is planned to have a 1,5 / 1 thrust to weight ratio. With a total peak thrust of 5,7

kg the weight limit for the prototype is 3,8 kg to achieve the same thrust to weight ratio.

As motor speed controller (or ESC = Electronic Speed Controller) I use a Hobbywing X-Rotor 20A ESC. Since the EMAX MT 2216 consumes 14.6A at full power,

a 20 Amp ESC should be sufficient, especially since no long duration flights are planned with the prototype.

Parts Required for Prototype

6 x EMAX MT 2216 motor (or similar)

6 x Hobbywing X-Rotor 20A ESC (or similar)

2 x 5000 mAh LIPO with min. 20 C (or similar)

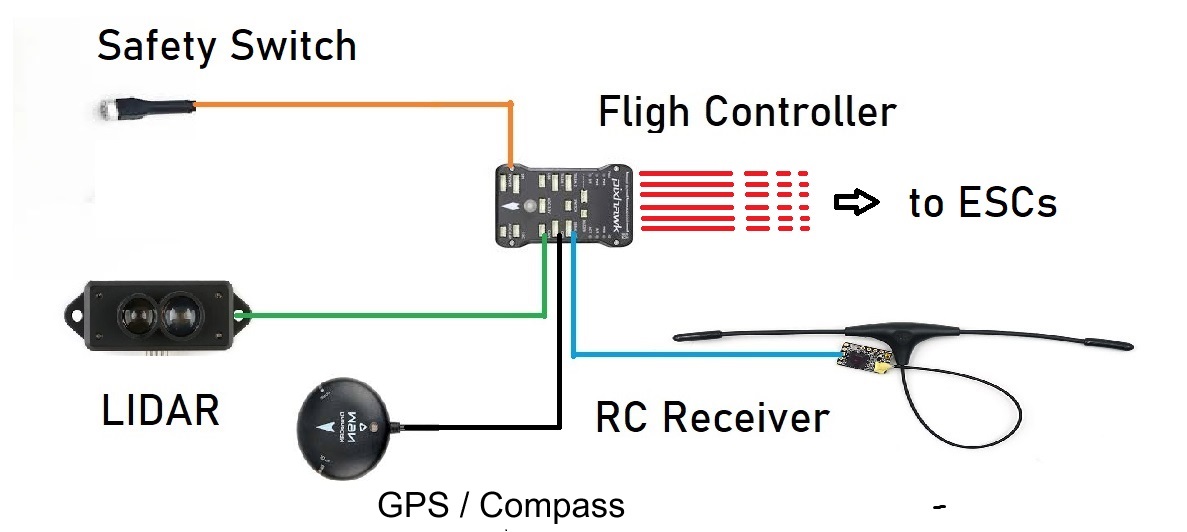

1 x Pixhawk Flight Controller

1 x LIDAR

Power

As batteries I use a set of 4S Lipos (14.8 V) which can at least provide 45 A to be able to use one battery for 3 motors. A 5000 mA battery is able to provide 45 A for more than 6 minutes, enough time for the planned test flights. You also have to make sure that the batteries have the C rating to be able to provide the current needed to get full thrust out of the engines. The C rating, quite simply, refers to the capacity of energy the battery can safely discharge, represented as a multiple of its overall capacity. Thus a 5000 mAh 20 C battery should be able to provide 100 Amp peak current (5A * 20C = 100A) - at least in theory. It is best to have a discharge rate overhead of 30%. For a 5000 mAh 20C battery a discharge with 45 Amps should be no problem.

Control = Key to Success

The most difficult thing about flying is to keep control of the aircraft at all times.

For this you need either a capable pilot, or a powerful flight computer, which has the

necessary sensors (IMU, GPS, lidar) to check and correct the flight attitude and position

at any time. Ideally you have both.

The first flight tests with both the prototype and the full-scale FlyRider aircraft will be carried out remotely

(for the prototype test flights there is no choice since its unmanned, for FlyRider ist just for safety reasons).

Flight Controller

Pixhawk is much more than a flight controller, pixhawk has set a standard for the entire industry, and today controllers from various vendors around the world are built to its specifications. Initially Pixhawk was a student project at ETH Zurich. Little did the team know that it would end up having such a large influence on the drone industry. Today it is one of the leading flight controllers for UAVs and drones.

GPS and Compass

I use the Holybro GPS and compass module as it is very easy to connect to Pixhawk and provides stable and accurate position data.

The whole setup for the FlyRider flight control system is pretty simple and that's a good thing! You should always keep in mind that in terms of safety, a component is at its best when it is not needed - what is not installed cannot fail!

Ardupilot

Pixhawk is a sophisticated flight controller, but only the hardware. Without suitable software it just can't work! Fortunately, there is a variety of software that can run on Pixhawk, my choice is "ArduPilot". ArduPilot is one of the most advanced and reliable open source autopilot software available, it has been under development since 2010. The software is capable of controlling almost any vehicle system imaginable, from conventional airplanes, multi-copters and helicopters to rovers, boats and even submarines.

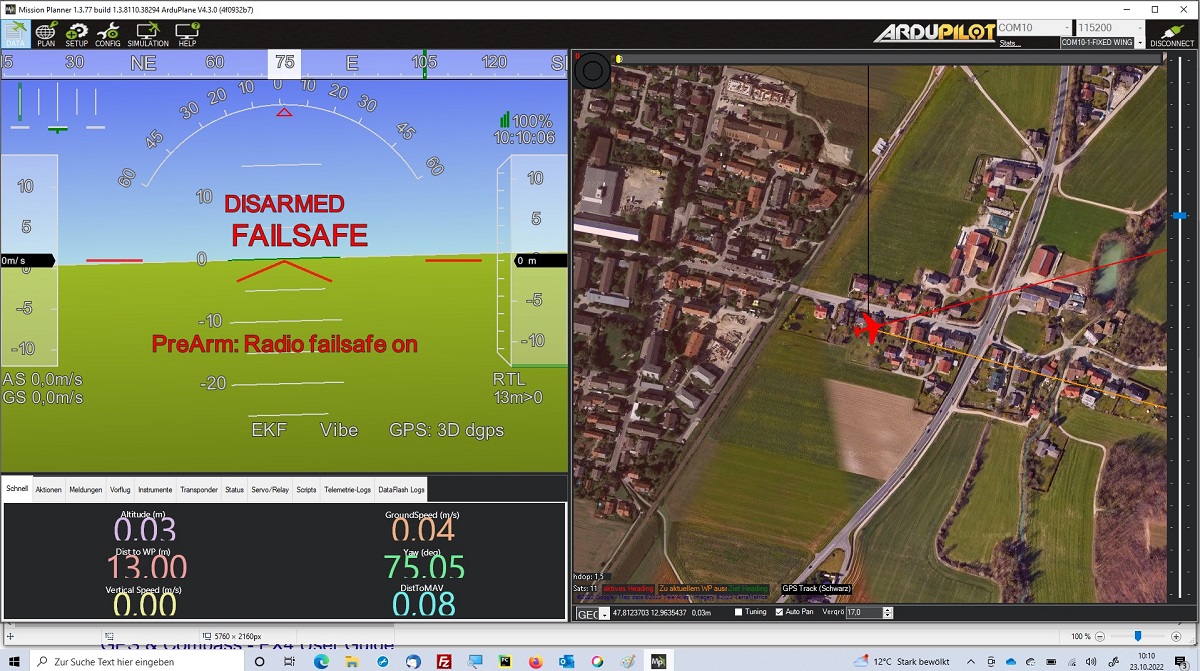

Mission Planer

Mission Planner (MP) is a full-featured ground station application for ArduPilot. Mission Planner can be used as a configuration

utility or as control supplement for ArduPilot controlled vehicles. With MP you can install the firmware into the flight-controller

hardware, setup and configuration your vehicle, plan autonomous missions with simple point-and-click way-point entry on maps,

download and evaluate mission logs created by autopilot and monitor the vehicle status while in operation.

Most importantly: All required settings for the flight controller can be made in Mission Planner.

Flight Controller Basic Setup

Make sure that you install the correct firmware on your flight controller hardware. The manufacturer strongly recommends to use only the firmware "FMUv3" with Pixhawk 2.4.8.

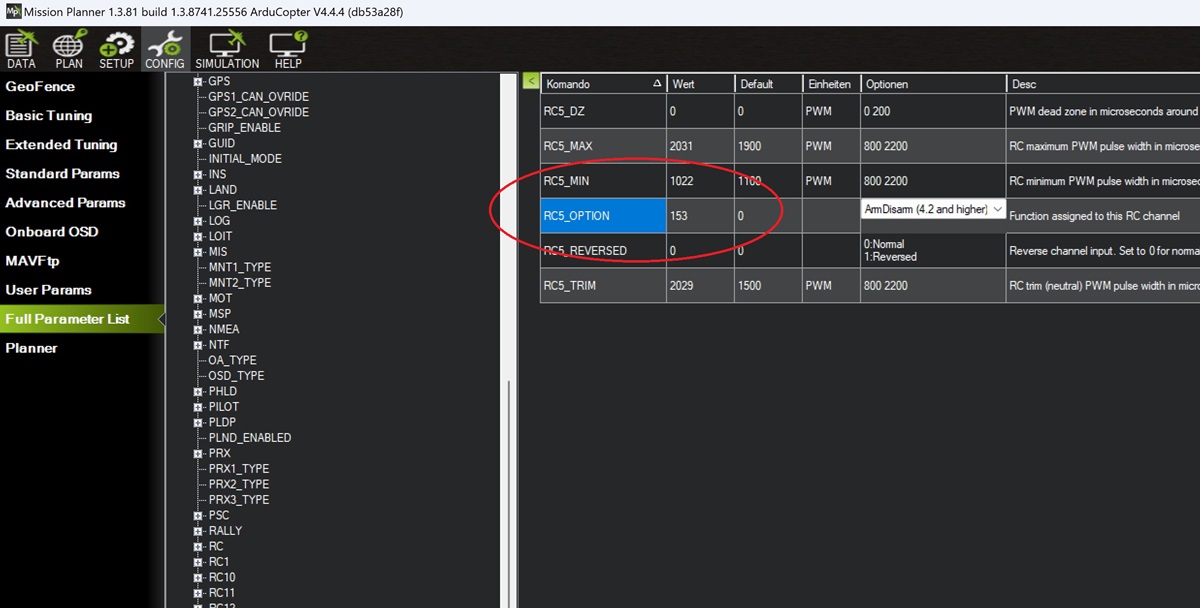

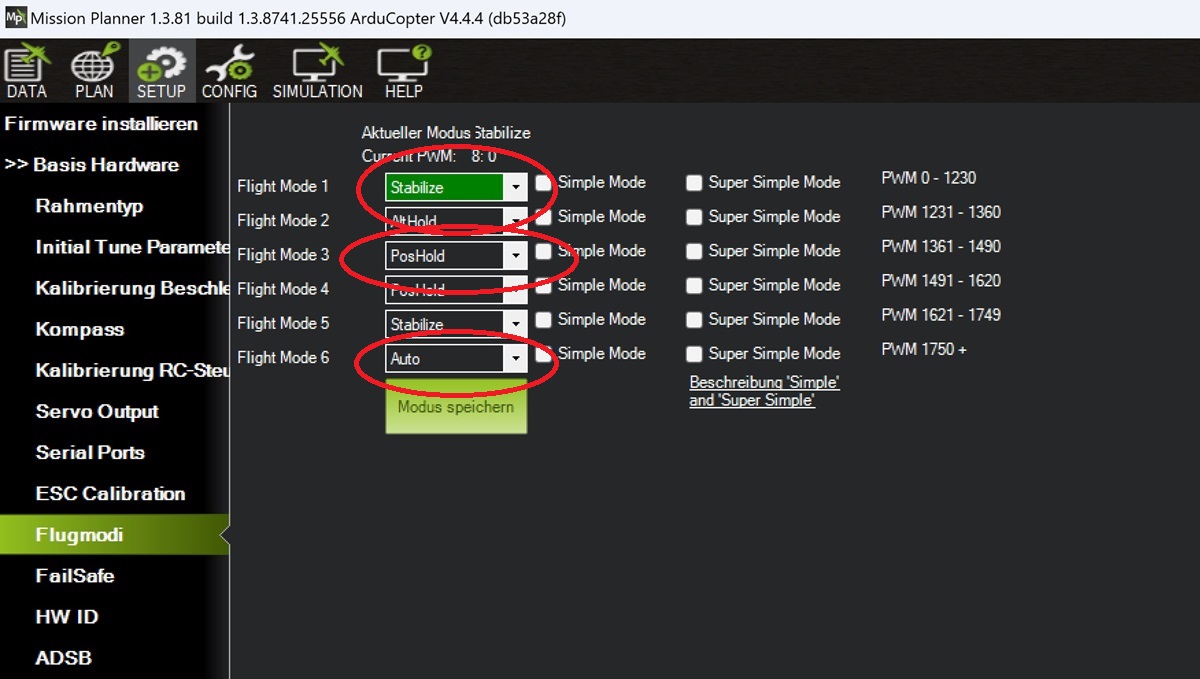

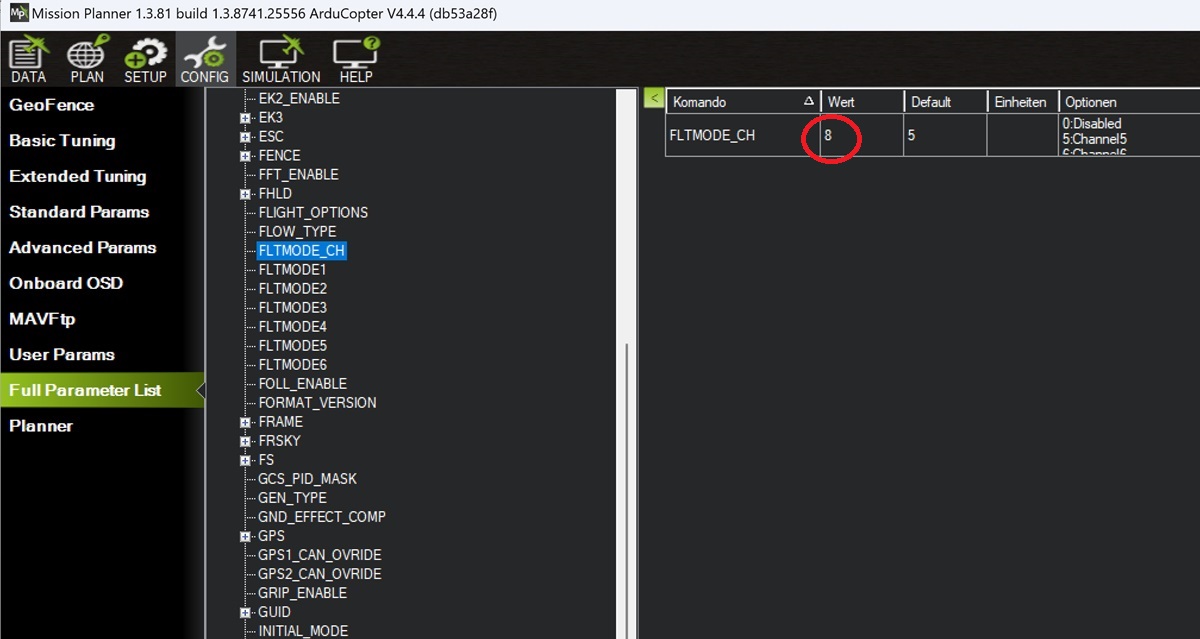

In the flight controller, channel 5 is used for arming and disarming, channel 8 is used to switch the flight modes:

FLTMODE_CH = 8 RC5_OPTIONS = 153

Flight Control Requirements

Clearly the most important requirement: stable flight and sufficient control authority.

Furthermore a sensible response should be defined for every possible failure situation. Possible

problems are, for example, loss of the remote control signal, low battery voltage or, in extreme cases,

motor failure.

The maximum flight altitude will be limited to 5 meters for safety reasons and to meet German air

regulations: any flying machine which is not capable of flying higher than 30 meters is by

definition no aircraft and does not fall under air law regulations. Flight altitude is

checked with a laser rangefinder installed on the underside of the aircraft.

Requirements - limiting the flight altitude to 5 meters above ground - limited forward speed (limited pitch angle) - speed backwards and sideways is limited to almost zero - if there is no active signal from the pilot, the aircraft automatically returns to a neutral flight attitude - in the event of a loss of signal, the aircraft lands automatically - a signal is triggered to the pilot in the event of critical battery capacity