STEP 3: BUILDING THE SIDE BOOSTERS

The side booster is mainly a tube with 60mm diamater and a length of 600mm. Together with the 94 mm cone nose we get an overall length of 700 mm, which fits well with the 1/60 scale. Within the tube we need the engine mount, a parachute buffle and a mount that connects the side booster with the core stage.

The Parachute Baffle

In most model rockets recovery wadding protects the recovery device (i.e., a parachute or streamer) from the heat of the ejection charge of the rocket motor. Without wadding, the parachute would be melted into a plastic wad, and the rocket would come down much too fast. In small rockets where the diameter is skinny, you only need a little bit of wadding to protect the chute. But as the diameter gets larger, it takes more and more wadding.

In larger diameter rockets, the alternative to wadding is to use a ejection charge baffle. They work by trapping the burning particles of the ejection charge. They also slow down the velocity of the gases, giving them a little bit of time to cool. Since I have just a single layer baffle, I will still use some recovery wadding to makes sure the parachutes will survive the heat of the ejection charge. The baffle is also needed as attachement point for the parachute system.

Connecting the Tubes

The 450mm tube is too short for the boosters, at a 1/60 scale the booster should have an overall length of 700mm. The nose cone is 94mm long, thus we need 150 mm extra lenght. I use the parachute baffle as connector, this gives me ~ 100 mm free space in the top section pf the tube which I need for the parachute, some recovery wadding and the back end of the nose cone.

Side Booster Test Run

Purpose of this test is to find out, if the ejection charge is able to eject the nose cone with the parachute and if all parts stay in place and can handle the heat of the ejection charge. Since we do not really want to launch the booster, we will just use two engines, both with ejection charge. During a real launch we will be two engines with ejection charge and two engines without.

Lessons learned: Even one ejection charge would do the job, the parachute baffle works fine. There is no damage at the parachute at all. That's the good part. The bad news is that my engine mount did not withstand the ejection charge. I need to build stonger mounts for the flight test.

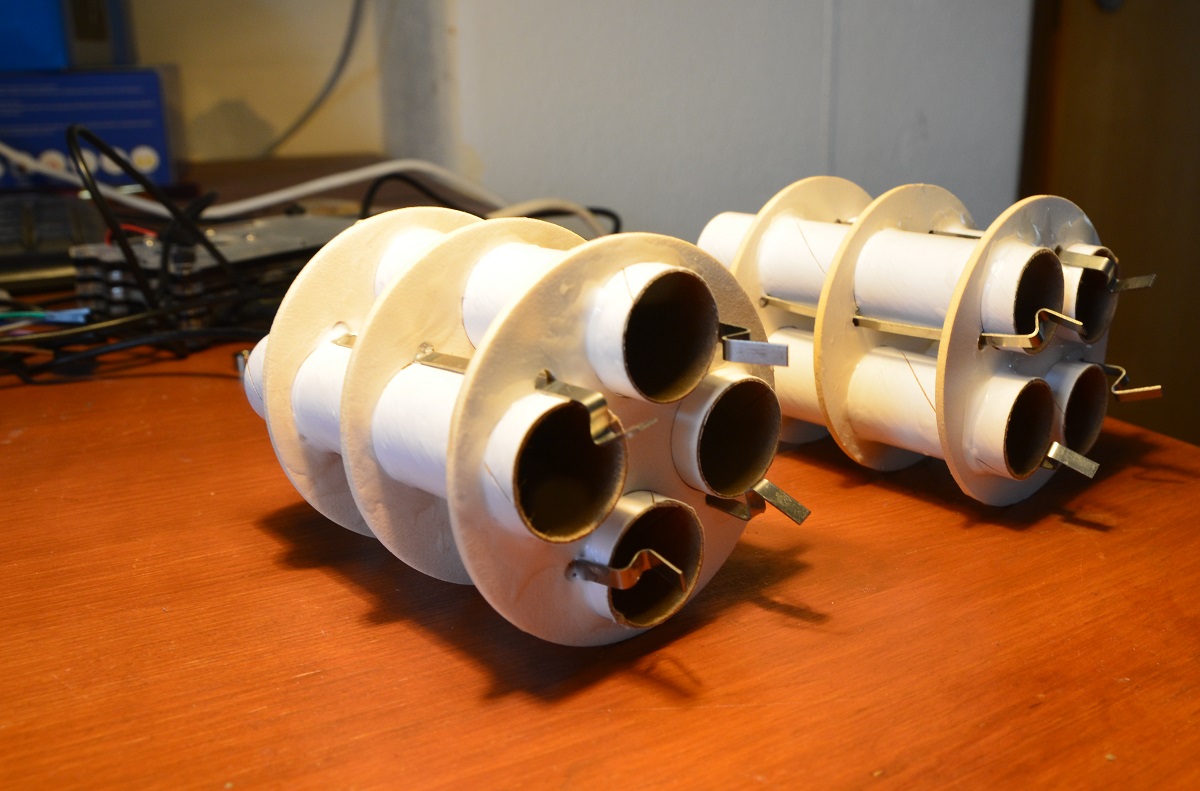

Improved Engine Mounts

The side booster engine mounts needs to be able to contain a cluster of four 18mm engines with 70mm length. There are cheap kits available containing the 18mm tubes, the engine hooks and the centering rings. Since my initial version failed, I have built an improved "heavy duty" version:

The Complete Booster

Each side booster gets a 70 cm parachute for recovery. With a current weight of 250 g without engines the parachute size fits well to the booster mass. I have added black "Block 5" grid fins without any function, just to make the model look a little bit more original, even if I do not intend to build a "scale model".